What are the cons of the ceramic coil in the pod system vape device?

Multi-hole ceramic material is a brand-new type of material, which is a ceramic body that has a three-dimensional skeleton structure after being fired at a high temperature, and it is distributed with a large number of three-dimensional channels internally.

This new type of ceramic material plays an extremely important role in the atomization process of electronic cigarettes.

Multi-hole ceramic materials can be sorted to various kinds, and the properties of materials vary depending on the purpose of use. Therefore, many different ceramic material firing techniques come out in recent years. Generally, the production processes of this kind of ceramics are granulation, mixing, molding, sintering, etc.

- Various complex shapes by different shaping methods;

- Various hole structures;

- High porosity;

- High strength;

- Especially suitable for ceramic body with closed holes;

- Suitable for producing microporous ceramic product;

- Suitable for production film material;

- Pores distributed uniformly.

Porous ceramics have a large thermal resistance and a small volumetric heat capacity due to high porosity, low density, and low heat transfer coefficient.

The application of porous ceramic materials has been used in various fields such as metallurgy, chemical industry, environmental protection, energy, biology, etc. In addition to the well-known space shuttle shell insulation, missile heads, filters, etc., it is currently playing a huge role in the field of electronic cigarettes.

The ceramic atomizing core is the standard coil for high-quality pod vape device. It adopts the porous ceramic structure and its pore size is of generally micron or sub-micron. It is generally called microporous ceramic atomizing core.

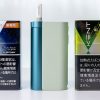

With the technology developing, now the ceramic heating element is used to the heat-not-burn device, a new type of tobacco heating system. More applications will be dug out in the near future.